Intelligent Manufacturing

TEBIS AUTOMILL

“Your expertise and your workshop mapped in Tebis process libraries”

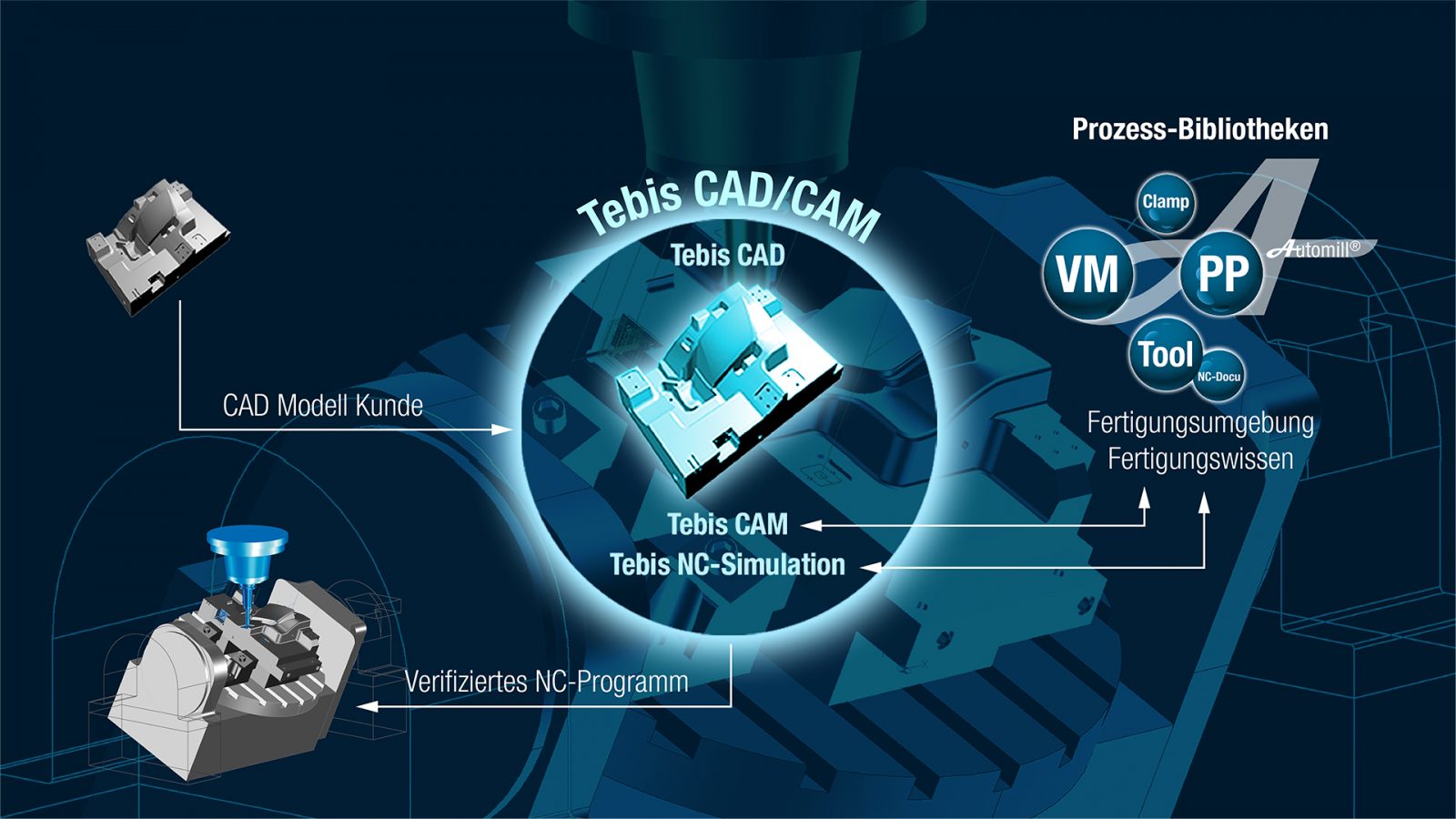

In Tebis CAD, the part is “intelligent” by virtue of your individual preparation work. Automated preparation instantly generates blanks, extensions, cover surfaces, guide curves and NC features. These are used by Tebis CAM.

Tebis CAM accesses process libraries containing your digitalized manufacturing environment and digitalized expertise and automatically calculates NC programs for 2.5D and 3D free-form geometry for milling, drilling, turning, turn-milling, wire and sinker EDM, laser hardening, laser cutting and laser weld cladding.

The integrated Tebis NC simulation generates verified NC programs in the control format

CNC PROGRAMMING

“For shorter programming and setup times”

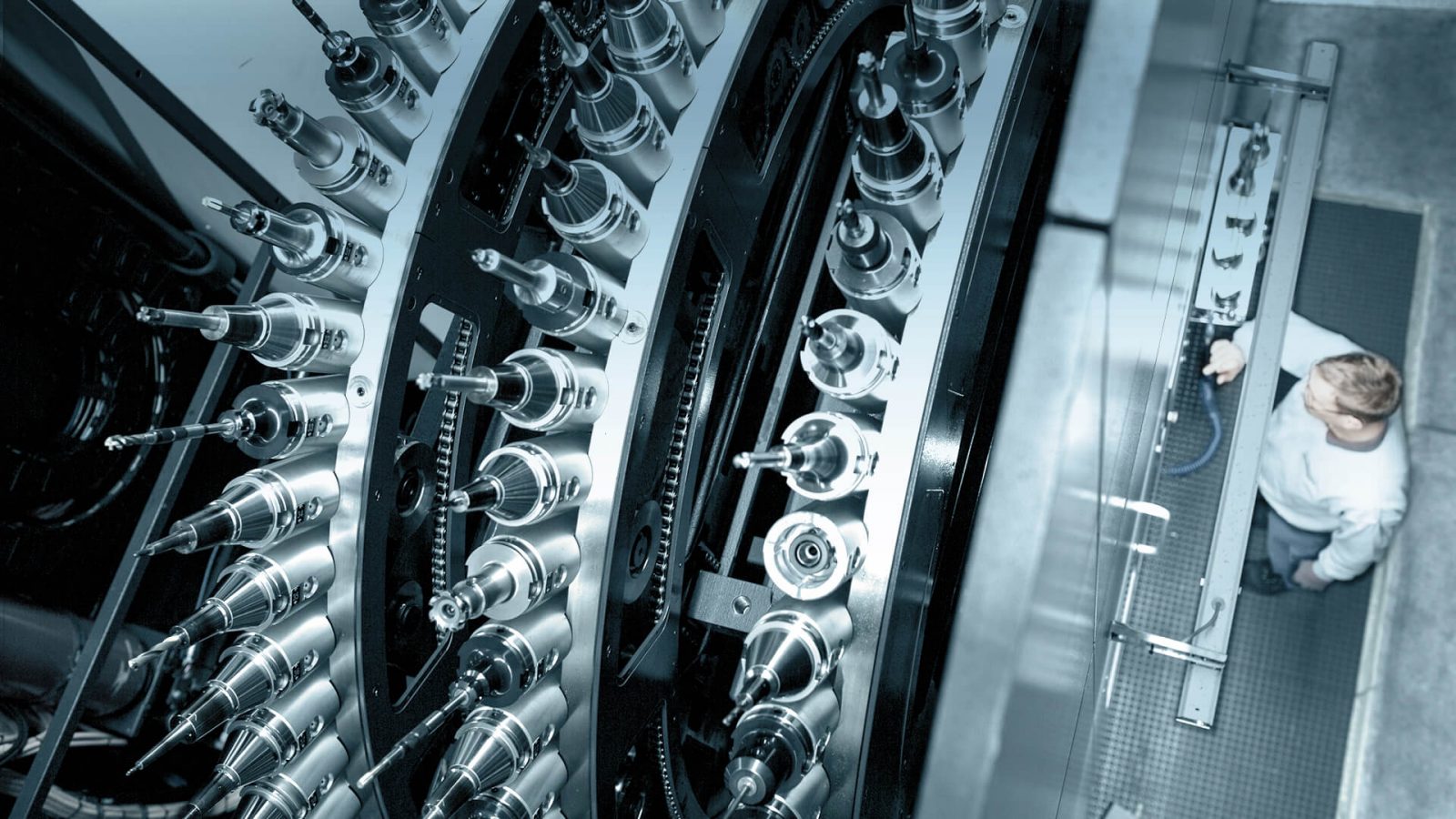

The time between order receipt and delivery deadlines in the manufacturing industry is becoming increasingly shorter. At the same time, components are becoming more complex and surface quality requirements are becoming more demanding. Programming and setup must be performed in parallel with machine uptime, and multiple machines must be effectively coordinated. Fluctuating order quantities and a lack of qualified personnel require highly dynamic and easily automated processes.

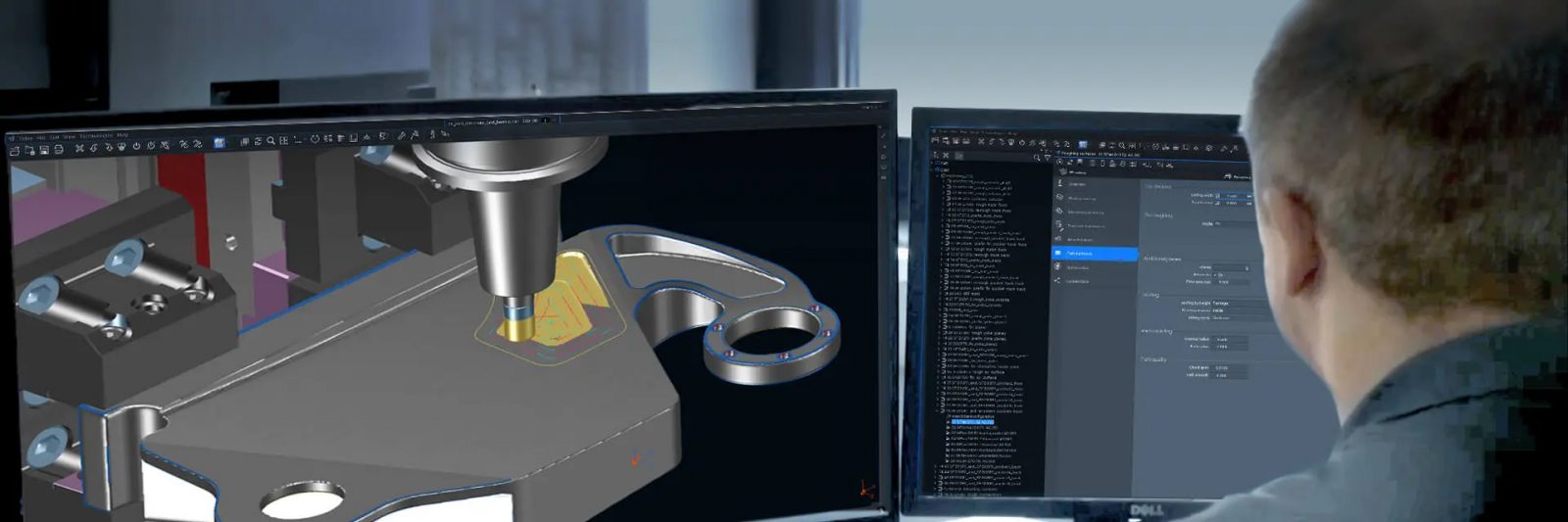

Tebis combines speed, reliability and a high degree of automation with the greatest possible flexibility in CNC programming and provides industry-specific solutions for all applications such as 2.5 D, 3D and 5-axis machining. All CNC programming solutions can be combined. Tebis lets you mill directly on surfaces or on meshes.

The manufacturing process with Tebis: You prepare CAD data for CNC programming: You use NC templates for highly automated CNC programming based on the structured data. Digital twins of your actual tools, machines and clamping devices and the entire manufacturing knowledge of your company are stored in your individual process libraries. If necessary, you can simulate and optimize the NC programs – these are then sent to the machine with complete collision checking.

CNC AUTOMATION

“Automatic manufacturing of single parts and small series with Tebis Automill® “

In modern manufacturing companies, NC programs for CNC machine centers are no longer created by conventional means with individual manual operations by an NC programmer on CNC controls and CNC programming systems. Instead, a CAM system like Tebis evaluates the digital CAD part model and accesses a previously stored structure of digital representations of the company’s manufacturing environment and the manufacturing knowledge stored in templates to calculate the NC programs. This forms the basis for automated CNC programming and highly efficient manufacturing.

CNC SIMULATOR

“Plan, program and check using digital twins”

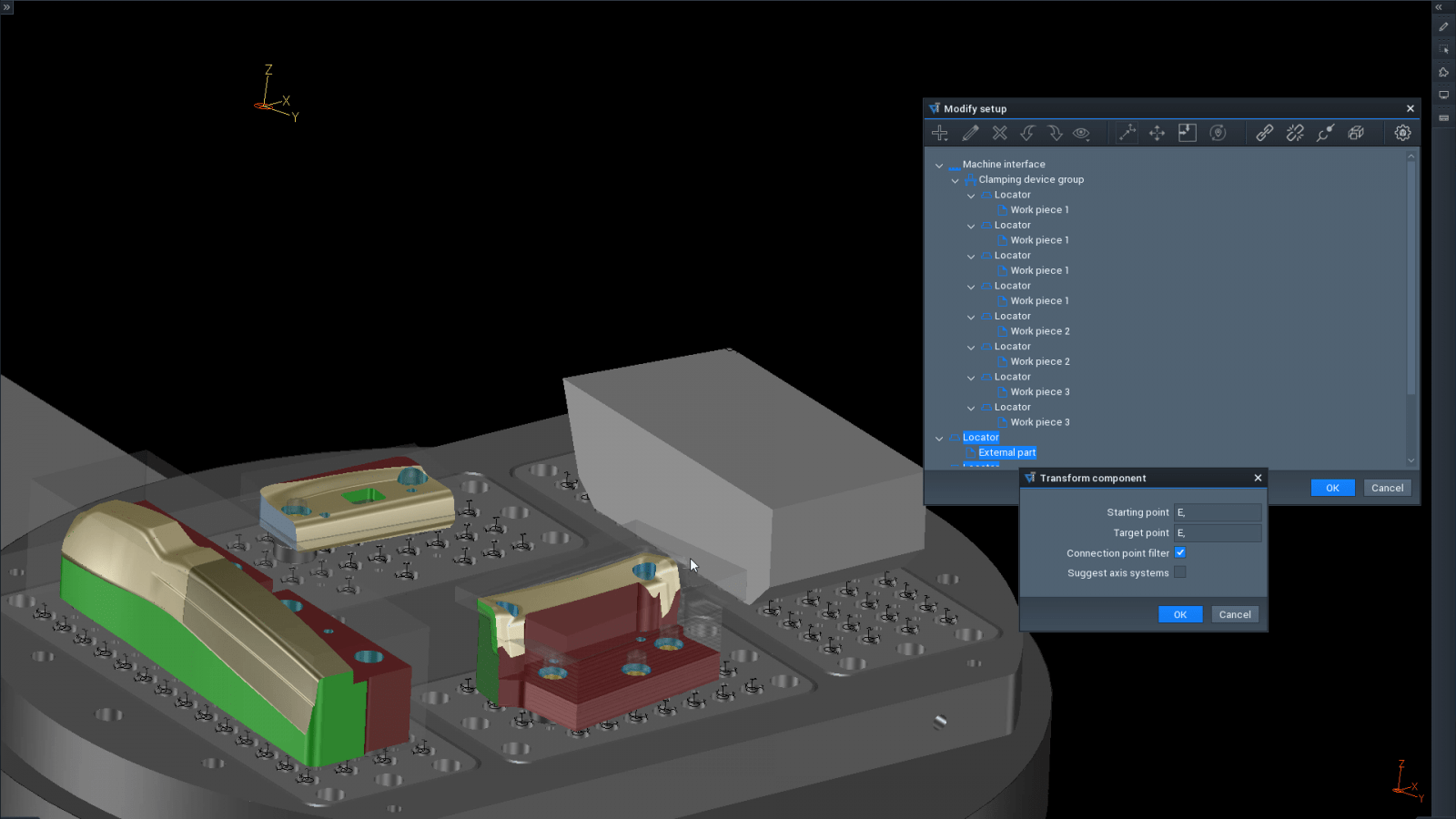

The Tebis CNC Simulator lets you fully plan, program and check your NC machining operations with all components in the Tebis NC programming environment. Prerequisite: All machines, tools, units and clamping devices are stored with components on a one-to-one basis as digital twins in the virtual manufacturing environment. This enables the detection and correction of potential collisions and limit switch problems before NC output. Synchronization with the postprocessor or networking with the machine are not necessary. Time-consuming and cost-intensive approach processes are eliminated. Use Tebis simulation technology to lay the foundation for multi-machine operation and reduced-personnel manufacturing.

MULTIPLE SETUP

“Save time with automated machining of multiple parts together”

Tebis lets you separate NC programming and setup planning with multiple setups. NC programming and machining can be done independently in terms of time and organization. Do you use grid plates, tombstones or multi-changers, or do you simply cover your large machine table with multiple parts? With Tebis, all situations are under control and you’ll optimally utilize your machines. All parts and clamping devices are protected from collisions. The previously calculated toolpaths are resorted to achieve the shortest possible paths and the fewest possible tool changes. And changes to the geometry are no problem – even just prior to manufacturing. Define your multiple setups with no programming knowledge.

ROBOTIC MACHINING

"Developing new applications with perfect NC programs"

You can easily integrate robots in your manufacturing processes with Tebis. Tebis supports robots for all types of machining. Because you’re programming with a virtual robot (digital twin) right from the start, there are no surprises later due to recalculation or other issues. Tebis directly outputs the NC control data for the robot. You can therefore proceed directly from the CAD data to the completed robotic machining program with no detours.

Contact Form

Address

Bursa

Alaaddinbey Mah. Ciftlik(380) Cad. No:7

16285 Nilüfer Bursa / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (224) 211 62 00

İstanbul

Sanayi Mahallesi Teknopark Bulvarı No:1/3A

Z04, 34906, Pendik, İstanbul / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (216) 521 53 85