Active Surfaces

"Enormous time savings in the tryout phase"

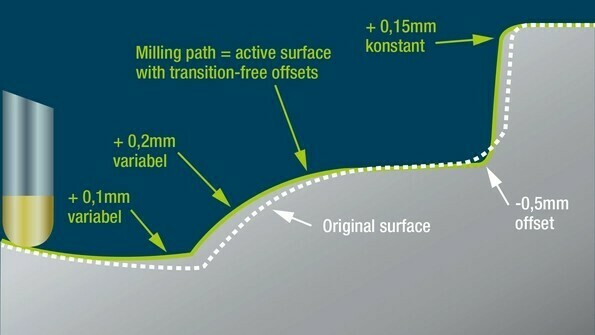

Because a large amount of time and effort is supposedly needed for design, active surfaces are often fully designed for only one side of the sheet metal (e.g. for the die). Offset dimensions (= sheet metal thickness) are then factored into the NC programs for NC manufacturing. Often stock allowances are also used in the NC programs to account for thinning effects and reliefs. Although this procedure quickly yields an initial result, it also requires an enormous amount of manual effort in the spotting presses and usually in additional iterations in tryout.

Tebis offers automated design functions with which active surface designers can include sheet thickness, thinning effects and reliefs in the design of the CAD active surfaces. This results in absolutely realistic tool sets – accounting for all known and simulated forming effects. This enables time savings of hundreds of hours in NC programming, machining and tryout.

Contact Form

Address

Bursa

Alaaddinbey Mah. Ciftlik(380) Cad. No:7

16285 Nilüfer Bursa / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (224) 211 62 00

İstanbul

Sanayi Mahallesi Teknopark Bulvarı No:1/3A

Z04, 34906, Pendik, İstanbul / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (216) 521 53 85